The Heart of Precision: Ohio CNC Machining

The Heart of Precision: Ohio CNC Machining

Ohio, a state known for its rich industrial heritage, has long been a hub for precision manufacturing. From the early days of the automotive industry to the modern era of advanced manufacturing, Ohio has consistently pushed the boundaries of innovation and technological advancement. At the forefront of this progress is the field of CNC machining, a process that has revolutionized the way parts are manufactured. In this article, we’ll delve into the world of Ohio CNC machining, exploring its history, benefits, and applications.

The Birth of CNC Machining

The concept of CNC machining dates back to the 1950s, when the first computer-controlled machines were developed. These early machines used numerical control (NC) systems, which relied on punched tape or cards to guide the machining process. The introduction of computer numerical control (CNC) in the 1960s marked a significant milestone, as it enabled the use of computers to control the machining process. This innovation paved the way for the widespread adoption of CNC machining in various industries.

Ohio’s Role in CNC Machining

Ohio’s involvement in CNC machining began in the 1970s, when the state’s manufacturing sector started to shift towards precision manufacturing. The region’s strong industrial heritage, combined with its access to major transportation routes, made it an attractive location for companies looking to establish operations. As the CNC machining industry grew, Ohio became a hub for precision manufacturing, with many companies setting up shop in the state.

Benefits of CNC Machining

So, what are the benefits of CNC machining? For starters, it offers unparalleled precision and accuracy, allowing for the production of complex parts with high tolerances. CNC machining also enables the rapid production of parts, making it an ideal solution for high-volume manufacturing. Additionally, CNC machining allows for the creation of complex geometries and shapes, which would be difficult or impossible to produce using traditional machining methods.

Applications of CNC Machining

CNC machining has a wide range of applications across various industries. In the aerospace industry, CNC machining is used to produce precision parts for aircraft and spacecraft. In the automotive industry, CNC machining is used to produce engine components, transmission parts, and other precision components. In the medical industry, CNC machining is used to produce precision instruments and implants.

Ohio’s CNC Machining Industry

Ohio’s CNC machining industry is thriving, with many companies operating in the state. From small, family-owned shops to large, multinational corporations, Ohio is home to a diverse range of CNC machining companies. These companies specialize in producing a wide range of parts, from precision instruments to complex machinery components.

Challenges Facing the Industry

Despite its many benefits, the CNC machining industry faces several challenges. One of the biggest challenges is the shortage of skilled workers, as many young people are not interested in pursuing careers in manufacturing. Another challenge is the need for ongoing training and education, as CNC machining technology is constantly evolving.

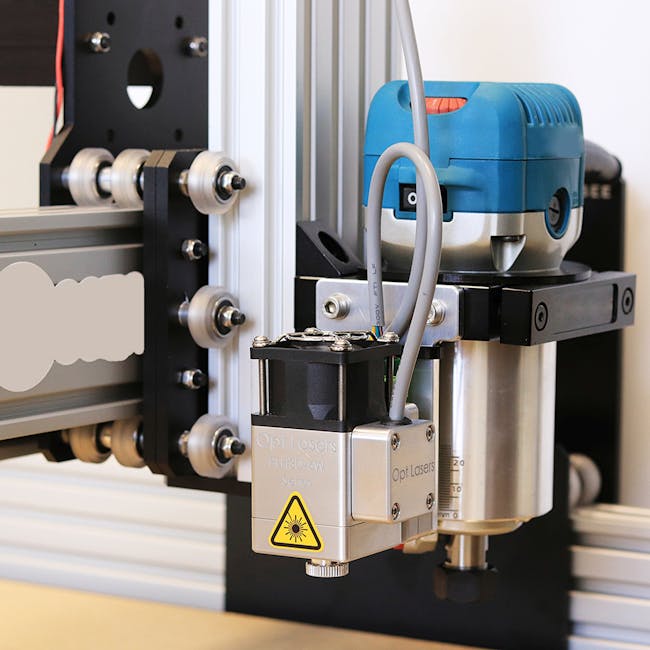

Innovations in CNC Machining

The CNC machining industry is constantly evolving, with new technologies and innovations emerging all the time. One of the most significant innovations in recent years has been the development of 3D printing technology. This technology allows for the rapid production of complex parts and prototypes, which has revolutionized the way companies design and manufacture products.

Ohio’s Response to the Challenges

Ohio is taking a proactive approach to addressing the challenges facing the CNC machining industry. The state has established several initiatives aimed at promoting workforce development and training, as well as providing incentives for companies to invest in the state. Additionally, Ohio is home to several research institutions and universities, which are working to develop new technologies and innovations in the field of CNC machining.

Conclusion

Ohio’s CNC machining industry is a vital part of the state’s manufacturing sector, providing high-quality jobs and driving economic growth. As the industry continues to evolve, it’s essential that Ohio takes a proactive approach to addressing the challenges it faces. By investing in workforce development and training, and by promoting innovation and entrepreneurship, Ohio can ensure that its CNC machining industry remains a key driver of economic growth and development in the state.